Aeration Made Simple !!!!

For Natural Oxidation of Hydrogen Sulfide and Iron, Features of the AP1 & AP2 Series Include:

- Plenty Of Dissolved Oxygen

- Availability of 115 volt and 230 volt

- Adaptation to existing aeration systems

- Easy installation

- No back pressure on well pumps

- No troublesome venturis

- Oil-less and medically safe

- Thermal protection

- Continuous Duty

- One year Manufacturer’s Warranty

- UL listed (AP1 CSA listed and AP2 CUR recognized)

The Physical Characteristics of the Air Pump are:

- Approximately 8 lbs. Pump weight

- 50 decibels Pump noise

- Water Resistance (Built for inside use—not to withstand rain or extreme wet conditions)

- Can withstand temperatures from 40 to 100 degrees Farenheit

- 20,000-25,000 Hours of use lifespan

- Aluminum body and components

- Stainless steel valves

- Teflon compression cup

- Rocking piston for air compression

- Induction (not commutator) motor

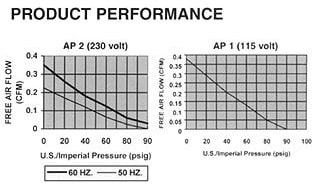

The Air Volume Production and Quality of the Air Pump is:

- Cubic feet per minute injection of air

- At 0 psi, AP1 injects .38 CFM & at 50 psi injects .15 CFM

- At 0 psi, AP2 injects .23 CFM & at 60 psi injects .07 CFM

- Oil-less, non-contaminated

- 70 psi recommended maximum operating pressure, can pump up to 100 psi

Maintenance Tips for the Air Pump Include:

- Self-lubricating (no oil)

- Replace Teflon compression cups every 12,000 hrs.

- Recommended annual inspection

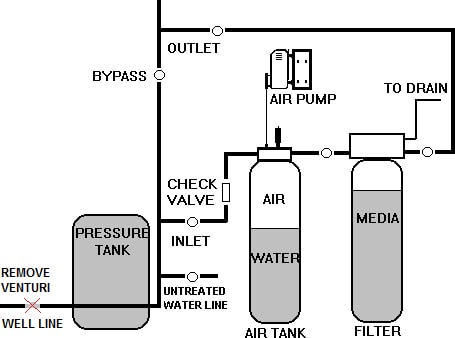

- Vertical mount installation is recommended to prevent moisture and debris from building up on valves and valve plates. (see diagram above)

Recommended Accessories Include:

Download and Print Tech Sheet:

Due to our excellent product and our years of experience, we are pleased to hold long-standing relationships with distributors from a local level to internationally. Our clients have worked in the industry for years, they use our products because they know it works.